Introduction

Knitting is a craft that has been around for centuries, and with the development of knitting machines, it has become easier and more efficient to produce knitted fabrics. Knitting machines come in many different types, and they all work in slightly different ways. In this blog post, we will explore how a knitting machine works and the different components that make up a knitting machine.

Table of Contents

- Introduction

- How a Knitting Machine Works

- Parts of a Knitting Machine

- Needle Bed

- Carriage

- Tension Mechanism

- Stitch Cam

- Conclusion

How a Knitting Machine Works

A knitting machine works by using mechanized needles to create loops and interlock yarns, forming fabric in a faster and more consistent manner than hand knitting. Now that we understand the components of a knitting machine, let’s take a closer look at how the machine actually works.

Step 1: Setting Up the Machine

Before you can begin knitting, you need to set up the machine. This involves attaching the yarn to the machine and threading it through the tension mechanism and the carriage. Once the yarn is in place, you can begin knitting.

Step 2: Creating the First Row

To create the first row of knitted fabric, you need to push the carriage across the needle bed. As the carriage moves across the needle bed, it pushes the yarn through the hooks on the needles, creating loops of yarn that form the knitted fabric.

Step 3: Reversing the Carriage

Once you have created the first row of knitted fabric, you need to reverse the carriage and move it back across the needle bed. As the carriage moves back across the needle bed, it creates another row of knitted fabric.

Step 4: Controlling the Stitch

The stitch cam is a component found in some knitting machines that controls the needle movements. The stitch cam rotates and controls the position of the needles on the needle bed, determining the type of stitch that is created. By adjusting the stitch cam, you can create a variety of different stitches and patterns.

Step 5: Adding Yarn

As you knit, you will eventually run out of yarn. To add more yarn, you need to tie a new piece of yarn onto the old piece and continue knitting. It’s important to tie the yarn securely to prevent it from coming loose and ruining your knitting.

Step 6: Finishing the Project

Once you have knitted the desired length of fabric, you can finish the project by removing the fabric from the machine and binding off the stitches. Binding off involves knitting the stitches together in a specific pattern to create a finished edge.

Parts of a Knitting Machine

A knitting machine has several different components that work together to produce knitted fabric. These components include the needle bed, carriage, tension mechanism, and stitch cam.

Needle Bed

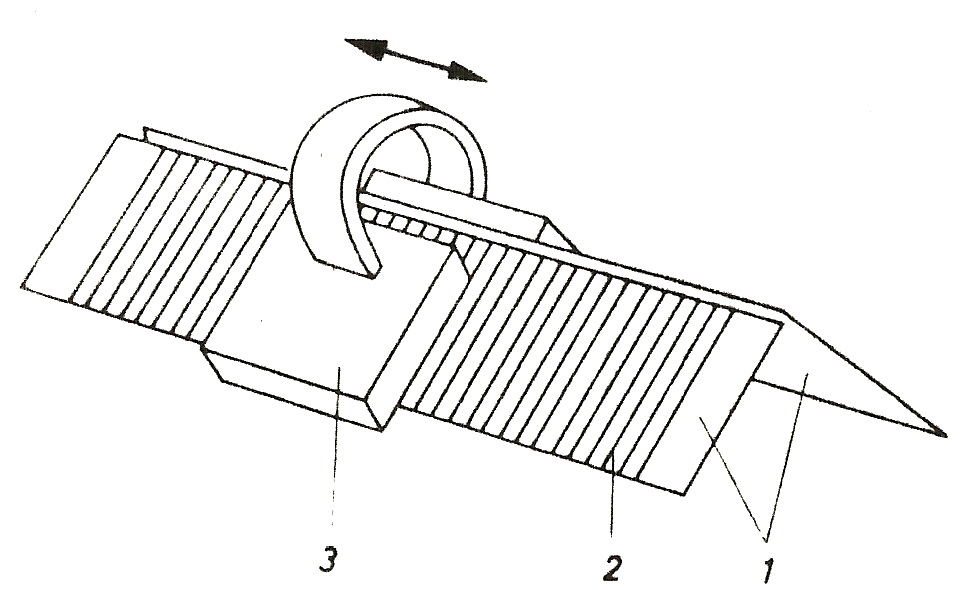

The needle bed is the part of the machine where the needles are located. The needle bed can be flat or circular, depending on the type of knitting machine. Each needle on the needle bed has a hook at the end that catches the yarn and pulls it through the fabric.

Carriage

The carriage is the part of the machine that holds the yarn and moves back and forth across the needle bed. As the carriage moves across the needle bed, it pushes the yarn through the hooks on the needles, creating loops of yarn that form the knitted fabric.

Tension Mechanism

The tension mechanism controls the tension of the yarn as it moves through the machine. The tension mechanism ensures that the yarn is pulled through the fabric evenly and creates a consistent stitch.

Stitch Cam

The stitch cam is a component found in some knitting machines that controls the needle movements. The stitch cam rotates and controls the position of the needles on the needle bed, determining the type of stitch that is created.

Conclusion

Knitting machines have revolutionized the knitting industry, making it easier and more efficient to produce high-quality knitted fabrics. By understanding how a knitting machine works, you can create beautiful, high-quality knitted items quickly and easily.