“If the machines are not running, we are not making money.” This is a phrase that is often heard in the textile industry. Machine maintenance is extremely important in the textile industry and cannot be ignored. Machines must be properly maintained in order to function properly and efficiently. If machines are not properly maintained, they can break down, which can cause production to halt and can be costly to fix.

Table of Contents

- What is maintenance in textiles?

- The Importance of Machine Maintenance in the Textile Industry

- The Consequences of Failing to Maintain Machines

- Preventive Maintenance in Textiles

- The Cost of Machine Maintenance

- The Benefits of Machine Maintenance

- Tools used for machine maintenance

- Conclusion

What is maintenance in textiles?

Maintenance is the process of keeping machines in good working order. It is necessary to prevent machines from breaking down and to keep them running efficiently. There are various types of maintenance, including preventative maintenance, predictive maintenance, and corrective maintenance. In the textile industry, machine maintenance is extremely important and cannot be ignored. Machines must be properly maintained in order to function properly and efficiently.

![The Note] Maintenance of printing machines: the key to maximum performance](https://www.blainesapparel.com/wp-content/uploads/2022/10/DSC_0669.jpg)

Preventative maintenance is a type of maintenance that is performed in order to prevent problems from occurring. It is typically done on a regular basis, such as monthly or yearly. Predictive maintenance is a type of maintenance that uses data to predict when problems are likely to occur so that they can be fixed before they cause any damage. Corrective maintenance is a type of maintenance that is performed after problems have already occurred in order to fix them.

In the textile industry, machine maintenance is extremely important and cannot be ignored. Machines must be properly maintained in order to function properly and efficiently. If machines are not properly maintained, they can break down, which can cause production to halt and can be costly to fix. Therefore, it is important for textile businesses to invest in machine maintenance in order to avoid these problems.

The Importance of Machine Maintenance in the Textile Industry

Machine maintenance is important in the textile industry for a number of reasons. First, if machines are not properly maintained, they can break down. This can cause production to halt, which can be costly to fix. Secondly, properly maintained machines tend to be more efficient than those that are not. This means that they require less energy to run, and they produce less waste. Finally, machine maintenance can save money in the long run by extending the life of the machine and preventing costly repairs.

There are a number of tools that can be used for machine maintenance. These include preventative maintenance programs, which help to identify potential problems before they occur; inspection programs, which help to identify existing problems; and repair and replacement programs, which address problems that have already occurred. By using these tools, the textile industry can keep its machines running smoothly and efficiently.

The Consequences of Failing to Maintain Machines

Failing to maintain machines can cause them to break down. When machines break down, production comes to a halt. This can be costly to the company as well as the workers. Failing to maintain machines can also lead to injuries.

If a machine breaks down, it can cause production to come to a halt. This is because the machine will need to be fixed before it can be used again. If the machine is not fixed in a timely manner, this can lead to a loss in production for the company. The workers may also be idled during this time, which can lead to a loss in wages. In some cases, the company may have to pay overtime wages in order to catch up on production.

Failing to maintain machines can also lead to injuries. If a machine is not properly maintained, it can malfunction. This can lead to injuries for the workers who are using the machine. In some cases, these injuries can be severe and even life-threatening.

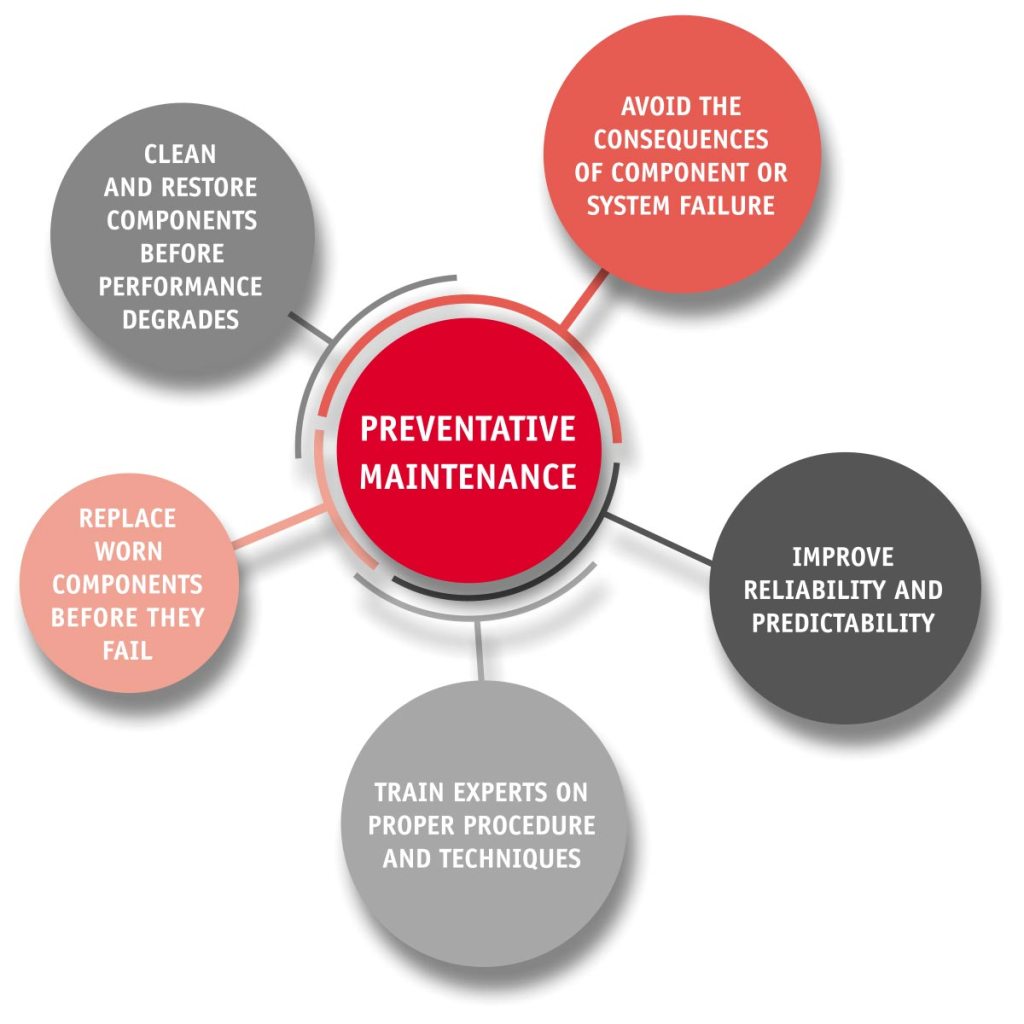

Preventive Maintenance in Textiles

Preventive maintenance has been shown to be a key way to increase revenue and decrease downtime. It can also help to lower the risk of equipment failure. By performing regular preventive maintenance, you can help to ensure that your equipment is running smoothly and that any potential issues are identified and addressed before they cause any real problems.

The Cost of Machine Maintenance

The cost of machine maintenance can vary depending on the type of machine and the severity of the damage. For example, a simple tune-up for a machine might cost a few hundred dollars, while a more extensive repair could cost thousands. Machine maintenance is often expensive, but it is necessary in order to keep machines functioning properly. If a machine breaks down, it can cause production to halt, which can be costly for a company.

The cost of machine maintenance can be a burden for textile companies, but it is worth the investment. Properly maintained machines will last longer and be more efficient, ultimately saving the company money in the long run. There are many ways to cut costs when it comes to machine maintenance. For example, companies can invest in preventative maintenance plans or purchase used machines instead of new ones.

No matter what measures a company takes to reduce the cost of machine maintenance, it is important to remember that machine maintenance is an essential part of running a successful textile business. Machines must be properly maintained in order to function properly and efficiently. Failing to do so can lead to costly repairs and production disruptions.

The Benefits of Machine Maintenance

When it comes to machine maintenance in the textile industry, there are many benefits that can be reaped. Perhaps most importantly, machine maintenance can increase the lifespan of machines. With regular maintenance, machines can last for years – even decades. In contrast, if machines are not properly maintained, they will break down more quickly and will need to be replaced more often. Not only does this mean that businesses will have to spend more money on new machines, but it also means that there will be more downtime while new machines are being brought in and set up.

In addition to increasing the lifespan of machines, machine maintenance can also improve the performance of machines. When machines are properly maintained, they run more smoothly and efficiently. This can help to speed up production and can result in a higher quality product. Additionally, well-maintained machines are less likely to break down, which means that production is less likely to be disrupted.

Another benefit of machine maintenance is that it can prevent costly repairs. If a machine is not properly maintained and breaks down, the cost of repairs can be significant. In some cases, repairs may even be more expensive than the cost of a new machine. On the other hand, if a machine is regularly maintained, small issues can be caught and fixed before they become big – and expensive – problems.

Finally, machine maintenance can minimize production downtime. As mentioned above, if a machine breaks down, production will come to a halt while repairs are being made. However, if machines are regularly maintained, they are less likely to break down and cause production disruptions. In other words, regular machine maintenance can help to keep the production line moving smoothly.

As these benefits illustrate, machine maintenance is extremely important in the textile industry. Machines must be properly maintained in order to function properly and efficiently. If machines are not properly maintained, they can break down, which can cause production to halt and can be costly to fix.

Tools used for machine maintenance

There are many different tools that can be used for machine maintenance in the textile industry. These tools are important for keeping machines running smoothly and efficiently. Some of the most common tools used for machine maintenance include:

– Oil cans: Oil cans are used to lubricate moving parts on the machine. This helps to prevent friction and wear, and keeps the machine running smoothly.

– Cleaning brushes: Cleaning brushes are used to remove dust and debris from the machine. This helps to keep the machine clean and free of build-up, which can cause problems.

– Screwdrivers: Screwdrivers are used to tighten or loosen screws on the machine. This helps to keep parts secure and in place, and prevents them from coming loose and falling off.

– Wrenches: Wrenches are used to tighten or loosen nuts and bolts on the machine. This helps to keep parts secure and in place, and prevents them from coming loose and falling off.

It is important to choose the right tool for the job, as using the wrong tool can cause damage to the machine. With proper care and maintenance, these tools can last for many years.

Conclusion

Machine maintenance in the textile industry is of the utmost importance. If machines are not properly maintained, they can break down, which can cause production to halt and can be costly to fix. The benefits of proper machine maintenance include increased efficiency and decreased downtime. To learn more this book can be read.